Highly efficient Biofuel Filtration and separation of clarified biodiesel from the transesterified Vegetable oil using a magnesium silicate dry wash procedure produces diesel fuel, capable of meeting or exceeding ASTM-D6571 requirements. Pilot scale filters and testing are available on site, or in our labs.

In the Dry Washing Step, impurities are adsorbed onto the magnesium silicate. Purified biodiesel liquid must then be separated from the solid dry wash adsorbent which is loaded with impurities. Following a final filtration, the clarified biodiesel will then be ready for storage. The solid by-product containing glycerin may be reprocessed or sold for a variety of uses including animal feed, fertilizer and soap

Large batch Biodiesel plant filtration applications are most cost-effectively served by ErtelAlsop ‘s EA-Series Recessed Chamber Filter Press technology.

EA-Series Biodiesel / Dry Washing Filter Press Units are available in a range of sizes. Every EA-Series Filter Press is engineered for peak performance in the specific biodiesel plant it is commissioned for.

Available with Recessed Chamber, or Diaphragm Squeeze Plates, and able to accommodate a wide variety of cloths, this line offers cake volumes from 0.5-300 cubic feet. Options such as plate shifters, automatic hydraulic closures and mobile cake carts are also available.

Available with Recessed Chamber, or Diaphragm Squeeze Plates, and able to accommodate a wide variety of cloths, this line offers cake volumes from 0.5-300 cubic feet. Options such as plate shifters, automatic hydraulic closures and mobile cake carts are also available.

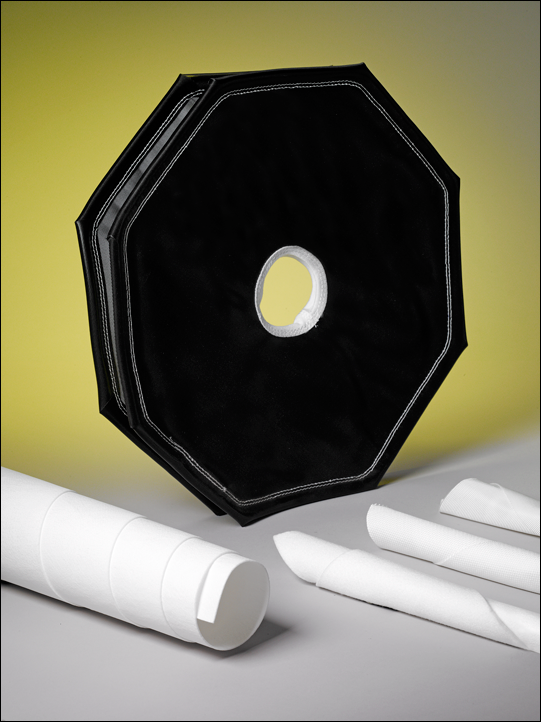

Filter Cloth

ErtelAlsop can provide a wide variety of filter cloth for your application. Please contact us directly for assistance in determining what is best for your specific requirements.