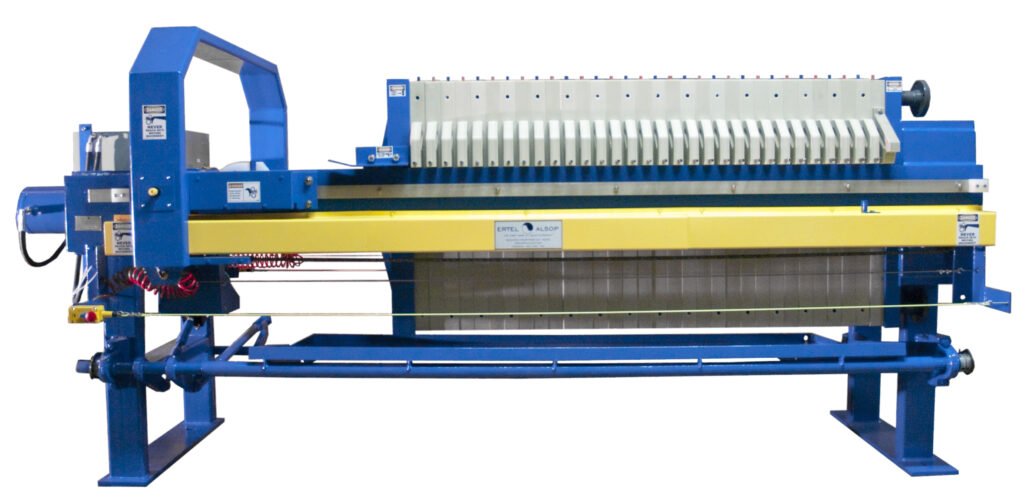

EA Series Filter Presses

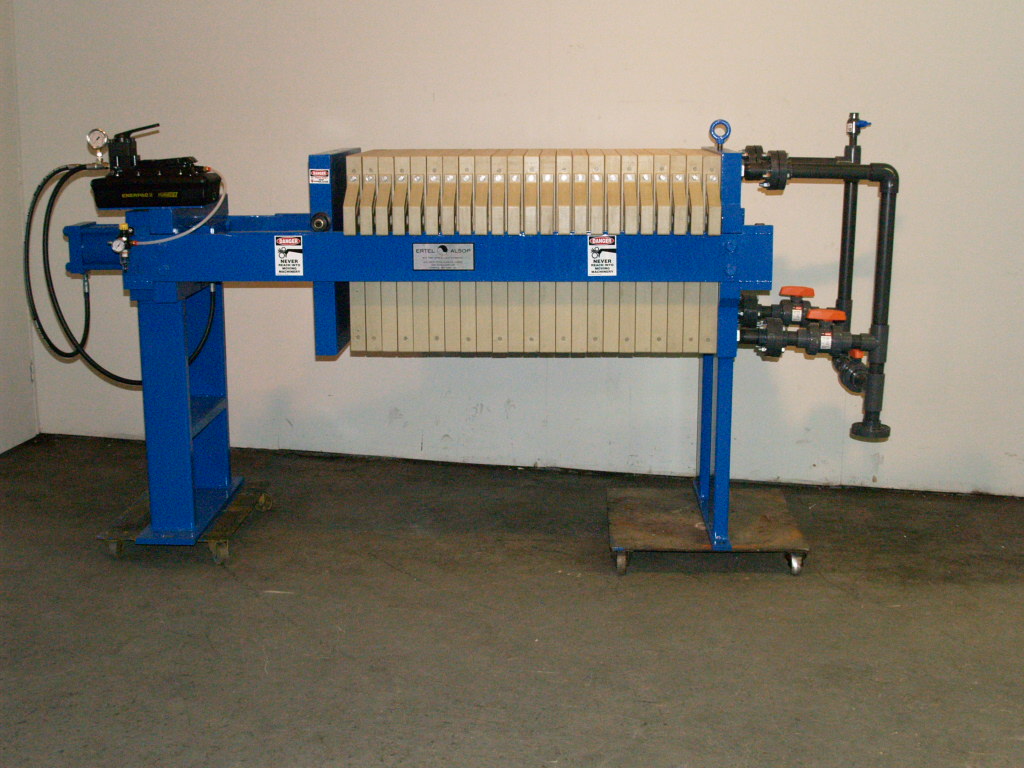

We observed, asked, and listened to hundreds of Recessed Chamber Filter Press owners and operators and incorporated their ideas and suggestions into our Recessed Chamber Filter Presses, the Industry leading EA-Series, which include fast acting hydraulic systems, uniform fill manifolds, safety lanyards, reverse core blow capability, chemically resistant painted surfaces, and four corner chamber discharge porting to reduce cycle time.

Our presses provide a simple reliable method to dewater solids into cakes of 25-60% total concentration. This provides clearer filtrate solutions than systems removing only free water.

The EA-Series line is available in different sizes for solids handling ranging from press capacities of 1 ft3 all the way to 300 ft3 . 32mm caulk and gasketed polypropylene plates are standard on all models making these heavy-duty presses well suited for applications which require leak-free processing.

ErtelAlsop engineers will work with you to design and manufacture the optimum piece of equipment, and/or complete system, for any application with specific focus on quality, productivity improvement, cycle optimization, cost reduction, and safety.

Our Recessed Chamber Filter Presses are among the most efficient means of liquid solid separation through pressure filtration, either for solution filtration or sludge volume reduction. A filter press provides a simple reliable method of high compaction pressure to compress and dewater solids into filter cakes of 25-60% total concentration. This provides clearer filtrate solutions than other filter press systems that only remove free water.

Thirty-two (32mm) millimeter gasketed polypropylene filter plates are standard on all models, making these heavy-duty filter presses well suited for applications, which require leak-free processing. Other standard features include a chemically resistant painted steel skeleton, 304 stainless steel bar wear strips, schedule 80 PVC head connections, four corner discharge, hydraulic closure system, and a full 6 year framework warranty.

ErtelAlsop engineers will work with you to design and manufacture the optimum piece of equipment, and/or complete system, for any application with specific focus on quality, productivity improvement, cycle optimization, cost reduction, and safety.

For more information regarding options and different configurations please see our page on How To Choose a Filter Press.

*As with all ErtelAlsop presses, filter cloth is available for any application and/or operating condition, and is chosen based on your specific operating conditions, the performance required by the filtering cloth, and criteria given to us by you and/or by sample processing we do in our lab. ErtelAlsop offers the widest varieties of filter cloth and construction techniques to provide good particle retention, clear filtrate, high flow rates, and dry filter cakes.

Where is a filter press utilized?

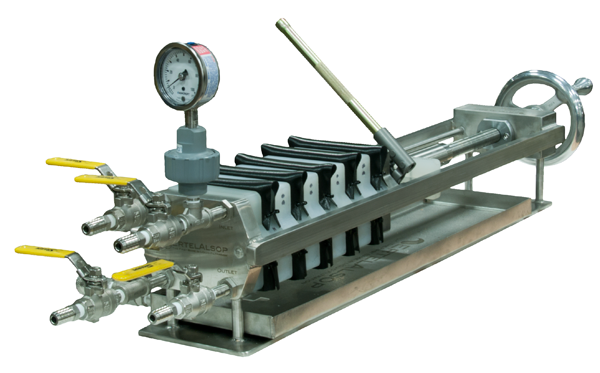

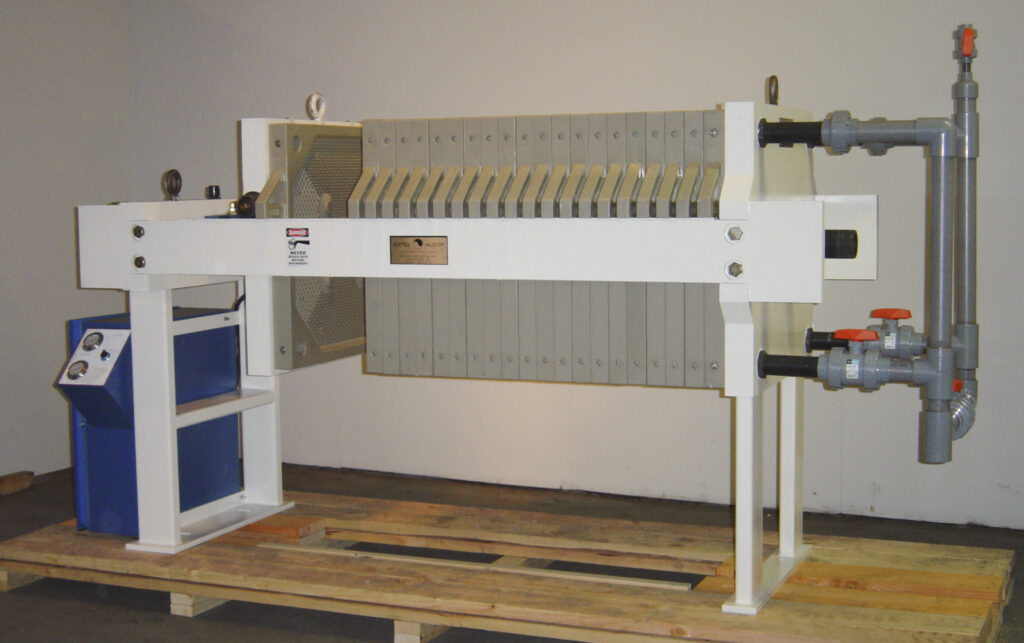

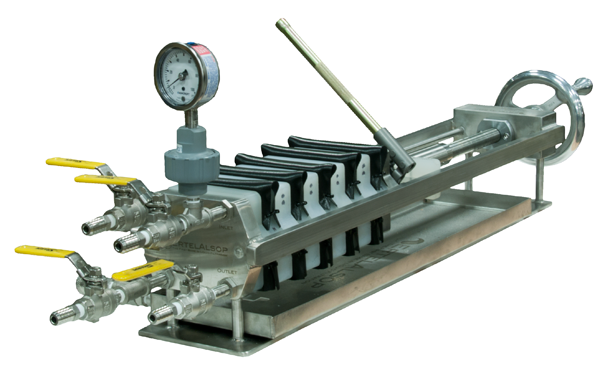

EA-102

The EA 102 Lab Recessed Chamber Filter Press are among the most efficient and cost effective means of liquid/solid separation through pressure filtration. EA Lab presses provide a simple reliable method of high compaction pressure to compress and dewater solids concentration. This provides clearer filtrate solutions than systems that only remove free water. This series of filters is designed for the laboratory, new product and process development, testing, scale-up and small volume production of products ( .01 to .05 cubic feet of solids handling). Cloth or paper changeover can be accomplished easily and in a minimum of time.

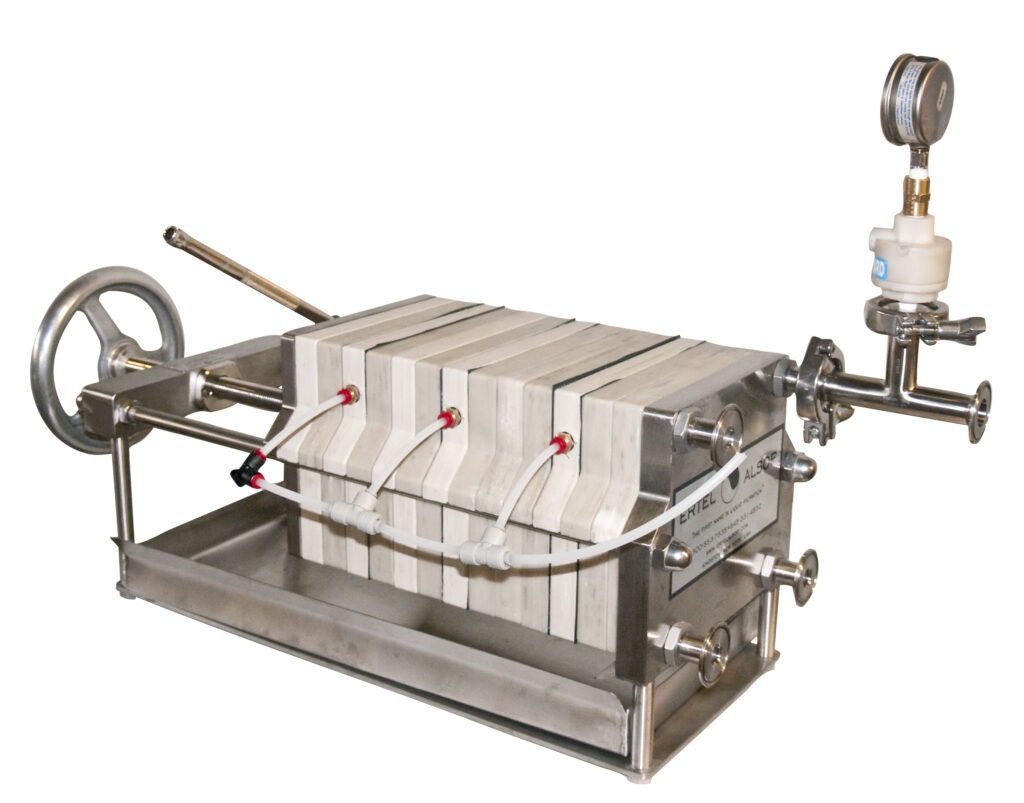

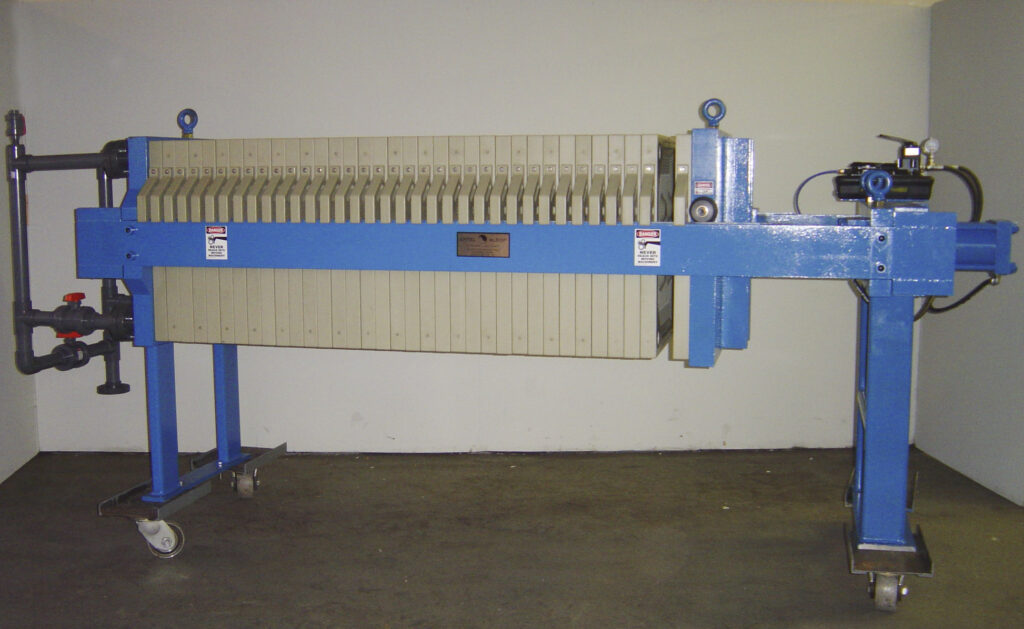

Request A QuoteEA-203

The EA 203 Lab Recessed Chamber Filter Press are among the most efficient and cost effective means of liquid/solid separation through pressure filtration. EA Lab presses provide a simple reliable method of high compaction pressure to compress and dewater solids concentration. This provides clearer filtrate solutions than systems that only remove free water. This series of filters is designed for the laboratory, new product and process development, testing, scale-up and small volume production of products ( .03 to .29 cubic feet of solids handling). Cloth or paper changeover can be accomplished easily and in a minimum of time.

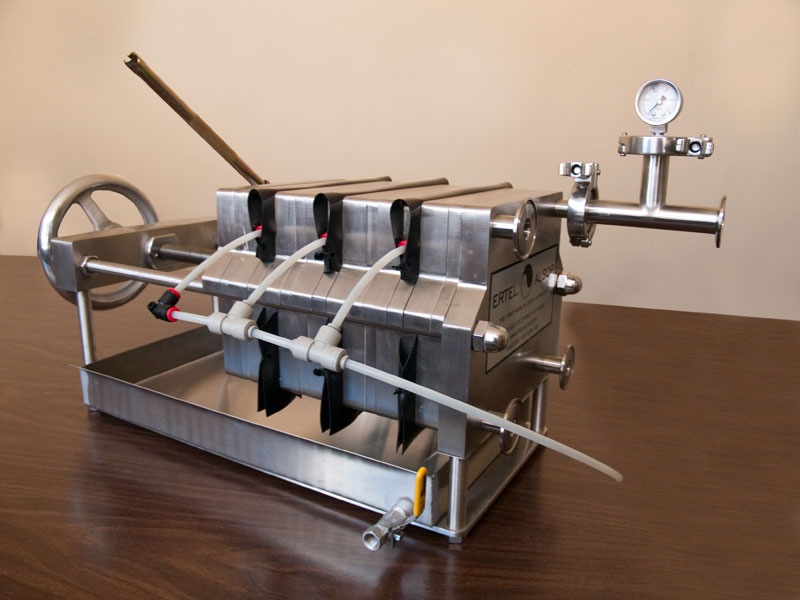

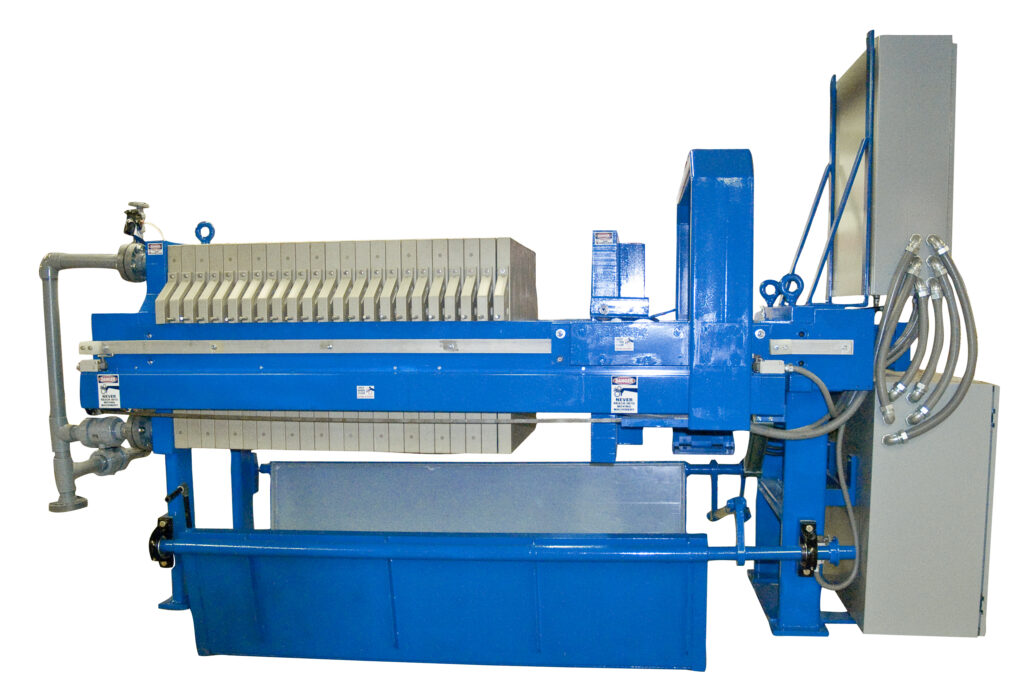

Request A QuoteEA-470

For use in a wide variety of applications, ErtelAlsop offers Model EA 470 Series Dewatering Recessed Chamber Filter Press systems. Supplied with lightweight, economical polypropylene plates, these filters are ideal for processes that require 0.5 to 2.9 cubic feet of solids handling. With gasketed plates standard, these heavy-duty presses are exceptionally suited for all applications where leakfree processing is required.

As with all ErtelAlsop Dewatering Filter Press models, filter cloth and optional features are available for any application and/or operating environment.

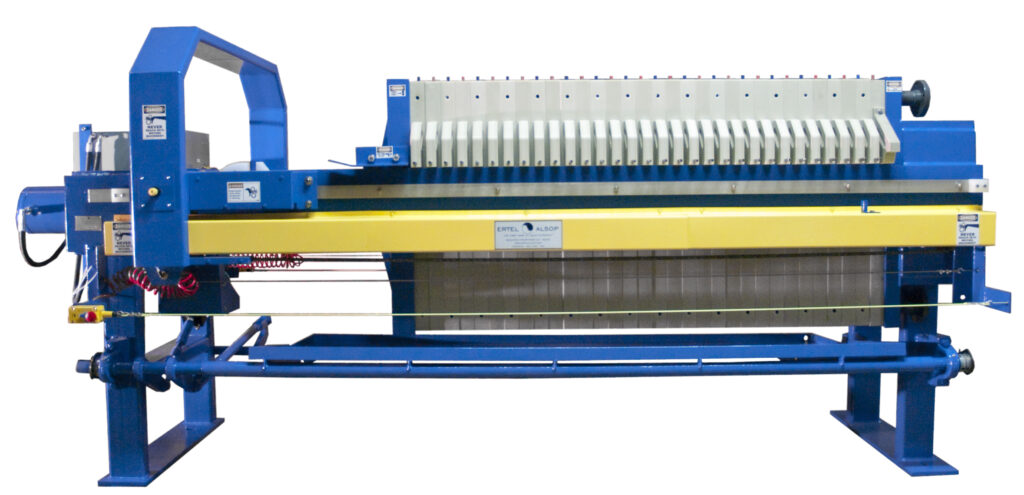

Request A QuoteEA-630

For use in a wide variety of applications, ErtelAlsop offers Model EA 630 Series Dewatering Recessed Chamber Filter Press systems. Supplied with lightweight, economical polypropylene plates, these filters are ideal for processes that require 2.9 to 10.00 cubic feet of solids handling. With gasketed plates standard, these heavy-duty presses are exceptionally suited for all applications where leakfree processing is required.

As with all ErtelAlsop Dewatering Filter Press models, filter cloth and optional features are available for any application and/or operating environment.

Request A QuoteEA-800

ErtelAlsop offers Model EA 800 Series Recessed Chamber Filter Press Systems for use in a wide variety of applications. Supplied with lightweight, economical polypropylene plates, these filters are ideal for processes that require 10 – 30 cubic feet of solids handling.

As with all ErtelAlsop plate and frame filter press models, filter cloth and optional features are available for any application and/or operating environment.

Request A QuoteEA-1000

ErtelAlsop offers Model EA 1000 Series Recessed Chamber Filter Press Systems for use in a wide variety of applications. Supplied with lightweight, economical polypropylene plates, these filters are ideal for processes that require 20-60 cubic feet of solids handling.

As with all ErtelAlsop plate and frame filter press models, filter cloth and optional features are available for any application and/or operating environment.

Request A QuoteEA-1200

ErtelAlsop offers Our Model EA 1200 Recessed Chamber Filter Press with lightweight, economical polypropylene plates. Ideal for processes that require 40 – 100 cubic feet of solids handling. These heavy-duty presses are suited for applications where leak-free processing is required.

As with all ErtelAlsop Recessed Chamber Filter Press models, filter cloth and optional features are available for any application and/or operating environment.

Request A QuoteEA-1500

ErtelAlsop offers Our Model EA 1500 Recessed Chamber Filter Press with lightweight, economical polypropylene plates. Ideal for processes that require 50-281.5 cubic feet of solids handling. These heavy-duty presses are suited for applications where leak-free processing is required.

As with all ErtelAlsop Recessed Chamber Filter Press models, filter cloth and optional features are available for any application and/or operating environment.

Request A Quote