ErtelAlsop Depth Filtration Systems for Cannabis Industry Excellence

From high quality water to achieving a clear and pure extract, excellence in filtration is crucial to the Cannabis Industry.

Extracts of the active ingredients from the Cannabis sativa plant are now common options for various applications in North America. Cannabis oil extracts can be further processed to make edible products or standard extracts like medical marijuana extracts or hemp oil.

The filtration stage of producing essential cannabis oil, medical marijuana, or hemp oil is key to ensuring product safety and quality regardless of the desired result.

That’s why reliable cannabis extract producers of medical-grade marijuana and hemp oil turn to precision equipment to achieve excellence in every aspect of the liquid product, from distillation, taste and smell to the right appearance.

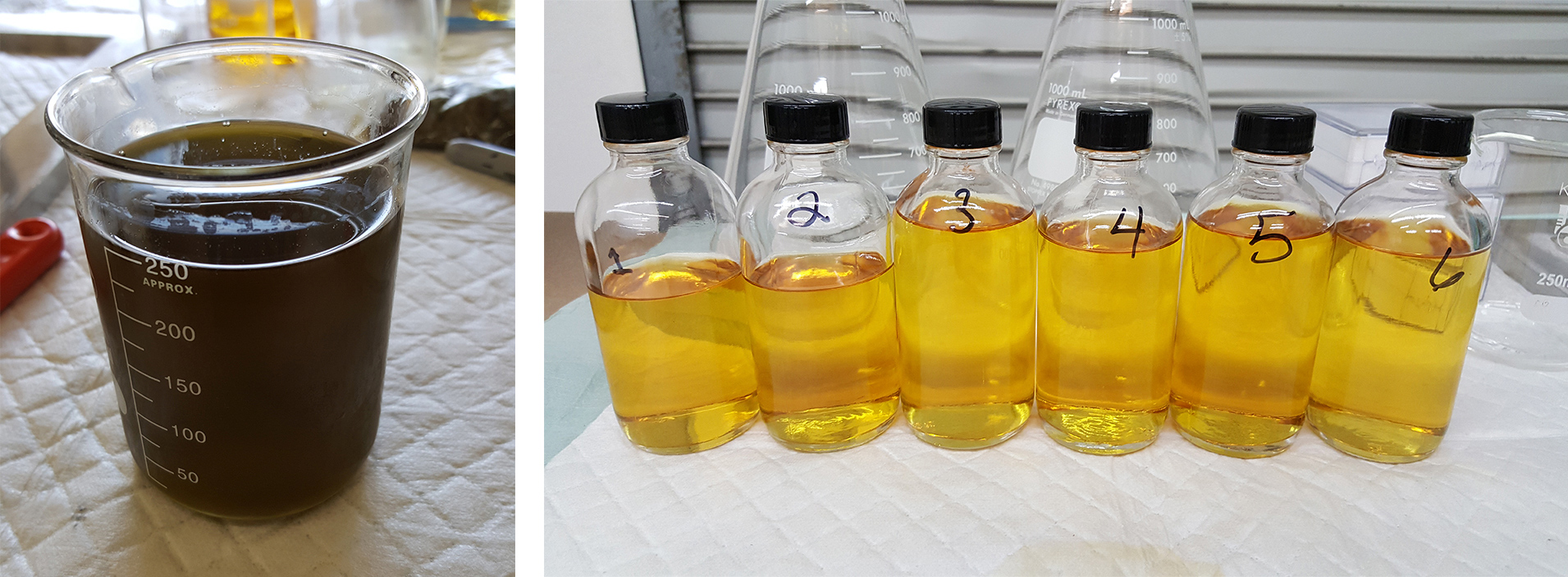

The right combination of proper techniques and tools is the difference between a clear, amber extract, and a muddy, undesirable product that contains plant particles, debris, and unwanted lipids.

From research and development applications in the laboratory, to full production runs, ErtelAlsop’s food grade depth filters, equipment, and filter media are staples for producers looking for a professional result.

ErtelAlsop has a variety of equipment for your cannabis filtration needs.

The 2-Step Filtration Process for Cannabis Purification

After CO2 extraction or cold ethanol extraction, the slurry is run through an initial filter stack. Most processes then pump the liquid through a filter that catches biomass. Finally, the liquid is pumped through another filter media grade as many times as necessary to remove unwanted compounds and finalize the product.

Step 1: Chlorophyll Removal

Achieve a clear product that can be applied to various applications. The muddy, dark brown or green appearance in the raw extract comes from the presence of chlorophyll. Activated carbon filtration effectively removes the chlorophyll, and adjusts the color and taste of your product without affecting its integrity.

The results above were achieved solely through activated carbon filtration, using ErtelAlsop’s Micro-Clear MC35C activated carbon filter media.

Step 2: Polish Your Product Before Bottling

Filter media like Micro-Media M704 with 0.45 micron retention finishes your product by removing fine particles and debris that can affect purity and appearance, and prepares it for final processing or bottling.

As with all ErtelAlsop filtration equipment, you’ll find the right filter media for your specific operating conditions. ErtelAlsop offers the widest varieties of filter media and construction techniques to provide good particle retention, clear filtrate, high flow rates, and dry filter cakes, with our variety of filter media finishes and separation capabilities.

- ErtelAlsop Micro-Clear™ Activated Carbon Filter Media is one of our most popular products used to improve purity and adjust color. Activated carbon sheets with varying pore sizes and premium adsorptive qualities allowing the removal of excess color and odor from liquids without having to deal with carbon in loose form.

- AlphaMedia G Series, the go-to premium filter medium for distilled liquids, essences, and oils, the G Series is a mineral-free depth filter medium without inorganic components. It has a net positive charge zeta potential, allowing for highly efficient removal of particles smaller than the filter’s nominal rating.

- For precision purity, clarity, and high throughput, the MicroMedia XL Series, featuring ultra-pure Celpure® diatomite that meets USP-NF standards, is the ultimate media for unparalleled process control. Manufactured specifically for critical applications, ErtelAlsop’s MicroMedia XL series depth filter sheets outperformed standard grades by over 500%.

Flexible Configurations, Easy-to-Use Equipment

We understand that the Cannabis industry relies on quality equipment to produce quality products.

Inventing filtration equipment since the 1930s, we’ve seen equipment come a long way. From our first lenticular cartridge format filter, to today’s modern evolution, every feature has been fine-tuned throughout ErtelAlsop’s lifetime to help you produce the best results.

Our products feature:

- Ergonomic, operator-friendly designs

- Fast loading and unloading

- Optimization for safety and efficiency

- Mix-and-match system component capabilities

- Compatibility with other system

To learn more about ErtelAlsop’s filtration options, explore more filter equipment and lenticulars.

Product Testing

Product filtration testing is always available, either at your facility through our network of distributors, or at our in-house laboratory.

Get personalized assistance to help you find what you need to enhance your process to produce quality in every batch.